Manufacturing

Digital Transformation Services

Revolutionizing Manufacturing with Digital Transformation

The manufacturing industry is undergoing a rapid digital evolution, requiring companies to modernize operations, integrate smart technologies, and enhance efficiency. Legacy systems and fragmented processes are no longer sufficient in an era where Industry 4.0, IoT, and AI-driven automation set the competitive standard. P&C Global’s Digital Transformation services help manufacturers transition to intelligent, data-driven operations by integrating cutting-edge technologies, enabling digital journeys for customers, streamlining supply chains, and optimizing the entire production lifecycle.

Harnessing Smart Technologies for Enhanced Productivity

With expertise in Industry 4.0, advanced manufacturing execution systems (MES), and digital product lifecycle management (PLM), we enable manufacturers to automate workflows, improve supply chain resilience, and enhance production agility. Our solutions integrate robotics, additive manufacturing, and edge computing to create highly responsive, intelligent manufacturing environments—ensuring efficiency, scalability, and competitive differentiation.

Digital Transformation Services for Manufacturing

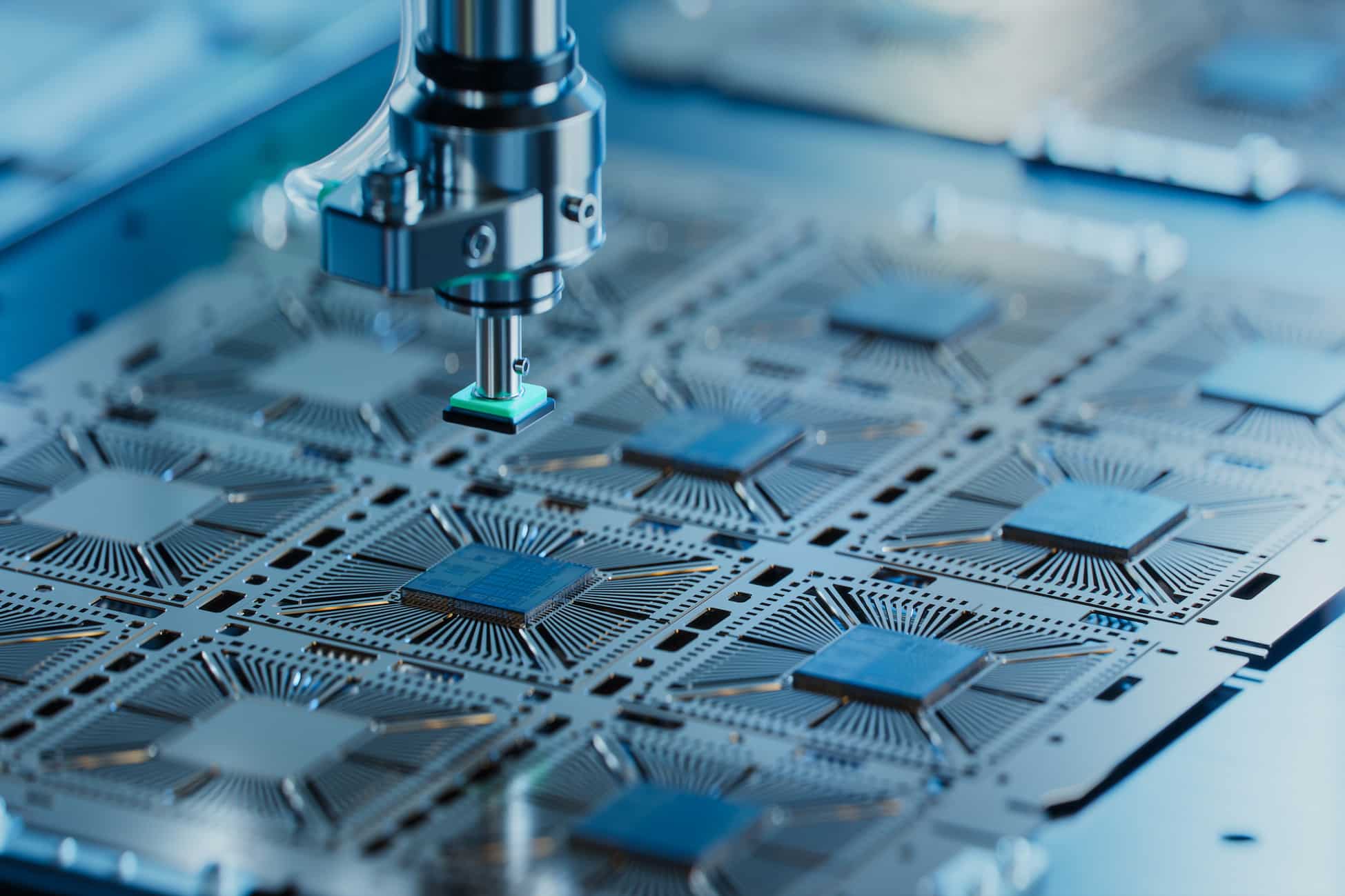

Industry 4.0 & Smart Factory Integration

We implement AI, IoT, and automation to create intelligent, adaptive production environments that enhance efficiency, improve quality control, and enable real-time decision-making.

Advanced Manufacturing Execution Systems (MES) Integration

We connect production systems with real-time data analytics and optimize MES frameworks to increase operational visibility, reduce downtime, and improve supply chain coordination.

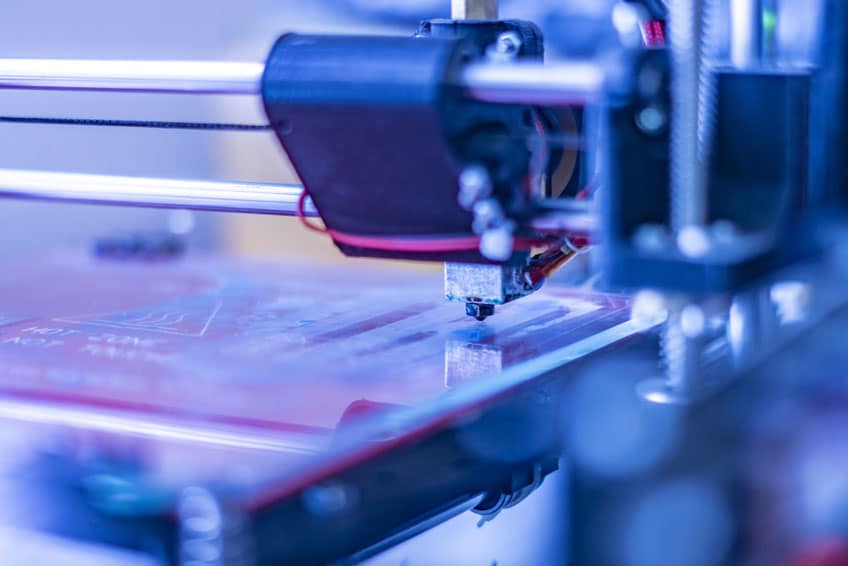

Additive Manufacturing & Advanced Materials Innovation

We leverage 3D printing and next-generation materials to streamline prototyping, reduce waste, and improve design flexibility, fostering innovation in manufacturing processes.

IoT-Enabled Customer Experience Solutions

We enable IoT solutions that connect smart products with cloud-based analytics, enabling manufacturers to deliver predictive maintenance, real-time customer insights, and personalized user experiences.

Omnichannel Commerce & Digital Retail

We integrate seamless omnichannel strategies, allowing manufacturers to enhance direct-to-consumer models, optimize eCommerce platforms, and improve customer engagement across digital touchpoints.

AI, IoT & Smart Logistics

Solutions

We implement AI, IoT, and blockchain technologies to optimize logistics networks, enhance shipment tracking, and increase supply chain efficiency through predictive analytics and automation.

Digital Twins for Logistic Network Operations

We use real-time simulation models, stress-test logistics flows, optimize transportation routes, predict and avoid disruptions before they impact operations.

3PL Data with ERP &

WMS Platforms

We enable seamless integration of third-party logistics (3PL) data with ERP and WMS platforms, enhancing end-to-end supply chain visibility and operational efficiency.

AI, IoT, & Blockchain for Shipment Tracking

We implement next-generation tracking systems powered by AI and blockchain to enhance transparency, reduce fraud, and streamline inventory management.

Edge Computing Solutions

We leverage edge computing frameworks to reduce latency, enhance security, and enable real-time analytics at the production level—supporting high-speed automation and intelligent decision-making.

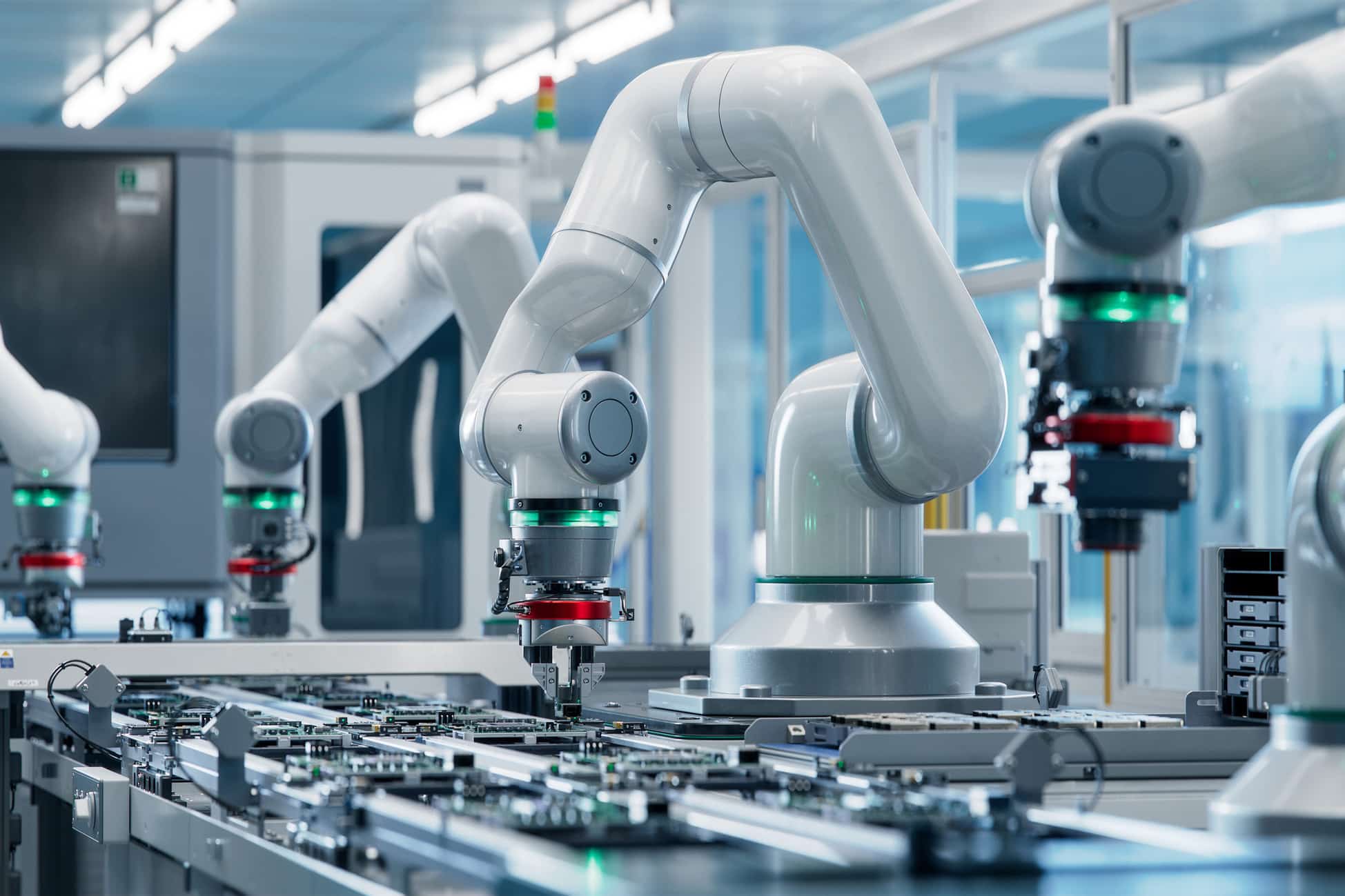

Robotics & Automation in Factories

We integrate AI-driven robotics and automation technologies to optimize labor-intensive processes, enhance precision, and improve manufacturing agility.

Enterprise Applications Integration

We facilitate the seamless integration of enterprise applications—from CRM and ERP systems. This ensures efficient workflows, improved data sharing, and enhanced decision-making across all business functions.

Digital Product Lifecycle Management (PLM) Solutions

We implement PLM solutions that centralize product data, streamline collaboration across design, production, and support teams, and accelerate go-to-market timelines.

Transform Your Digital Manufacturing Strategy

P&C Global helps manufacturers adopt digital transformation strategies that align with operational goals, customer demands, and emerging industry trends. By leveraging AI, automation, and connected ecosystems, we enable organizations to streamline production, optimize supply chains, and drive sustainable growth.

From Vision to Execution: Enabling Digital Adoption

We support manufacturers throughout the transformation journey—from strategy development to technology implementation. We ensure seamless digital adoption with minimal operational disruption, helping businesses achieve measurable improvements in efficiency, cost reduction, and market agility.

Future-Proofing Manufacturing Operations

We implement smart manufacturing, IoT, and AI-powered automation and provide customized digital solutions that enhance productivity, ensure data security, and future-proof operations. Together, we can build a more intelligent, agile, and resilient manufacturing ecosystem that drives long-term success.

Transform Manufacturing Digital Strategy & Execution

P&C Global engages manufacturing leaders through trusted introductions and long-standing relationships to drive innovation, enhance manufacturing productivity, and streamline operations.

Frequently Asked Questions — Manufacturing Digital Transformation Advisory

How does P&C Global differentiate itself from legacy consultancies such as McKinsey, BCG, and KPMG in manufacturing digital transformation?

P&C Global stands apart by delivering operator-led execution, not just advisory. Our teams consist of former manufacturing C-suite executives, plant leaders, and supply-chain specialists who have built and scaled global industrial operations.

Unlike many advisory-only firms, we own the outcome from strategy through implementation, deploying our proprietary Visage™ AI platform and advanced analytics to deliver real-time transparency into cost, performance, and risk. With absolute vendor-neutrality (no commissions or cross-selling), high team continuity, Swiss-level discretion and a 100 % client re-engagement rate, we deliver measurable, sustained impact that many legacy firms struggle to replicate.

What are the biggest drivers and disruption forces shaping digital transformation in manufacturing today?

Manufacturers are experiencing a convergence of transformative forces— automation, digitalization, supply-chain de-risking, sustainability mandates and shifting workforce models. The key catalysts include IoT integration, cloud and edge computing, AI/ML, digital twins and cyber-physical systems that blur the boundaries between digital intelligence and physical production.

To lead in this new era, executives must move beyond legacy “lift-and-shift” thinking to value-led transformation—where technology, data and operations converge to enable agility, resilience and new business models.

How should manufacturing leaders structure a digital-transformation roadmap to deliver measurable business results?

Effective roadmaps start with value-lever identification, followed by pilot execution, scalable architecture, and tightly governed roll-out. P&C Global helps define strategic KPIs (e.g., throughput improvement, cost-to-serve, time-to-market), build modular platforms, and maintain governance through our Visage™ AI platform. By linking strategy to measurable outcomes and embedding change governance early, we ensure transformation moves beyond proof-of-concept into enterprise-scale success.

How does digital transformation interact with legacy systems, operations and manufacturing continuity?

Successful digital transformation demands modernization without operational disruption. P&C Global employs a “modernize-without-disrupting” framework that integrates cloud, edge, and digital twin technologies with existing legacy architectures to enable seamless transition and interoperability. Through phased migration, predictive monitoring, and Visage™ and advanced analytics, we safeguard production stability while accelerating modernization. This approach minimizes downtime, mitigates risk, and ensures that transformation enhances—not interrupts—performance, resilience, and cost efficiency across global manufacturing operations.

What measurable outcomes have manufacturers achieved through P&C Global’s digital transformation programs?

P&C Global’s operator-led digital transformation engagements consistently deliver quantifiable, enterprise-level impact across the manufacturing value chain. Our clients have achieved:

- 40% faster time-to-market through streamlined product development and connected digital workflows

- 25% productivity gains driven by advanced manufacturing systems, automation, and predictive analytics

- 35% improvement in sales performance, with customer satisfaction exceeding 95%, through omnichannel integration and digitally enabled service models

These outcomes demonstrate how our execution-focused, AI-powered approach turns digital transformation into a sustained performance advantage—enhancing speed, scalability, and profitability across global manufacturing networks.

What role do emerging technologies—AI, digital twin, cloud, and robotics—play in manufacturing digital transformation?

Emerging technologies form the intelligence core of modern manufacturing transformation. AI and machine learning power predictive maintenance, quality optimization, and dynamic scheduling. Digital twins create real-time, data-rich simulations that enable precision control across assets and processes. Cloud and edge architectures deliver the scalability and resilience required for global operations, while robotics and automation drive speed, accuracy, and flexibility across production lines.

P&C Global integrates these technologies within end-to-end transformation architectures—aligning innovation, operations, and business strategy to unlock measurable performance, resilience, and competitive advantage.

What should manufacturing executives look for when selecting a digital transformation consulting partner?

Executives should prioritize partners who offer:

- Operator-led teams with real and proven manufacturing leadership experience

- Full end-to-end execution—not just strategy

- Proven data- and technology-integration capability

- Vendor-neutral stance (no commissions or cross-selling)

- Strong team continuity and ethical independence

- Trusted by clients with a 100% reengagement rate

P&C Global uniquely meets these criteria, delivering transformation anchored in business outcomes, not just agendas.

If a capability—such as quantum-enabled manufacturing, autonomous production ecosystems, or digital twin command centers—isn’t listed on your site, does that mean you don’t offer it?

Not at all. P&C Global routinely leads highly specialized, confidential digital transformation initiatives across next-generation manufacturing technologies—including quantum-process optimization, autonomous production networks, AI-driven predictive control systems, and digital twin orchestration. Many of these engagements remain undisclosed to protect client confidentiality and competitive advantage.

The capabilities featured on our site represent only a curated selection of our broader expertise. We invite senior manufacturing leaders to connect with us directly to explore bespoke, outcome-driven solutions engineered to advance your digital transformation agendas.

Success Stories

A dynamic showcase of P&C Global’s transformative engagements and the latest industry trends.

Demonstrated Outcomes. Significant Influence.

Witness the remarkable achievements we’ve enabled for ambitious clients.

Revolutionizing Home Appliances: Smart Customizable Clothing Irons

Establishing a Luxury Automotive Brand Via a High-Performance Hypercar

Redefining Elegance: French Airline’s Long-Haul Cabin Transformation